Example 1

Assumption

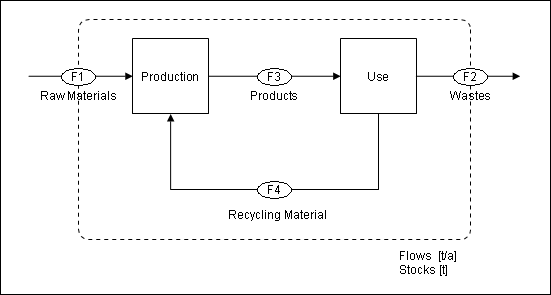

Within a region, products are created from imported raw materials and recycling materials. The products are sold and used within a year. A part of it is reused in the production and the rest is exported from the region as wastes.

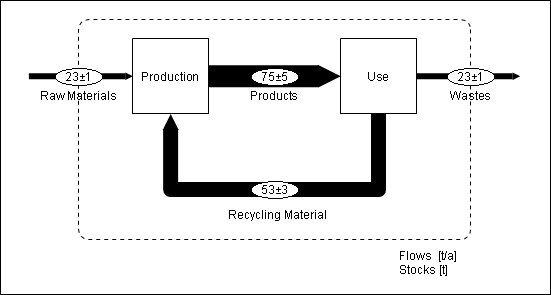

Figure: Default System

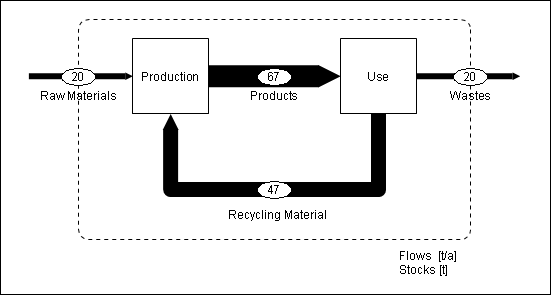

Calculate all flows for the following input data:

Question 1

Raw Materials = 20 t/a, Recycling Rate = 0.70

Figure: All unknown flows can be calculated. Because there is no stock within the system the waste export must be the same size as the raw material import.

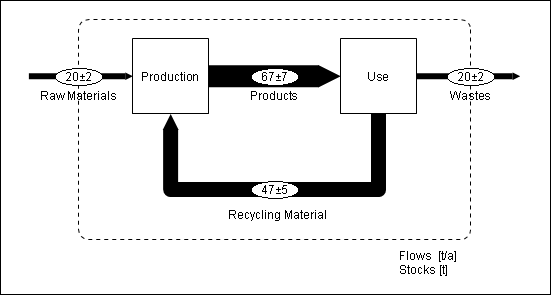

Question 2

Raw Materials = 20 ± 2 t/a, Recycling Rate = 0.70

Figure: All unknown flows can be calculated. The uncertainty of the raw materials import influences all of the unknown flows. All flows have the same relative uncertainty (10%).

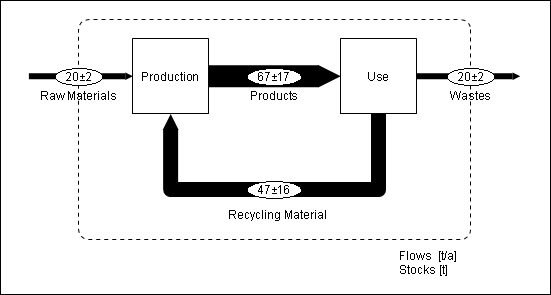

Question 3

Raw Materials = 20 ± 2 t/a, Recycling Rate = 0.70 ± 0.07

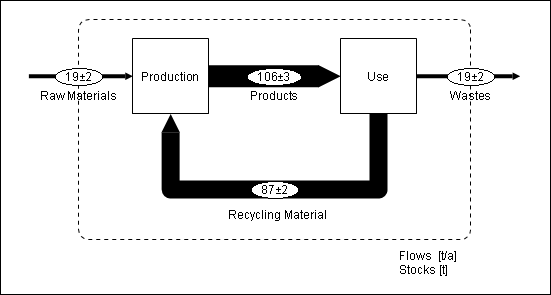

Figure: All unknown flows can be calculated. Because the mathematical system is nonlinear (uncertain flow * uncertain transfer coefficient) the uncertainty of the products and recycling materials flow is raised considerably.

Question 4

Raw Materials = 20 ± 2 t/a, Wastes = 25 ± 2, Recycling Rate = 0.70

Figure: The mathematical system describing the model is over determined (3 equations: 2 balances + 1 TC, 2 unknowns: product, recycling material). Because of that data reconciliation is possible. Raw materials and wastes are reconciled so that the system import equals the system export. Additionally their uncertainties are reduced.

Question 5

Raw Materials = 20 ± 2 t/a, Products = 100 ± 4, Recycling Material = 90 ± 3, Recycling Rate = ?.

Figure: The mathematical system describing the model is over determined (3 equations: 2 balances + 1 TC, 2 unknowns: products, recycling materials). Because of that data reconciliation is possible. The flows raw materials, products and recycling materials are reconciled so that the balance of the process production matches. Additionally their uncertainties are reduced.

Recycling Rate = 0.82 ± 0.02.